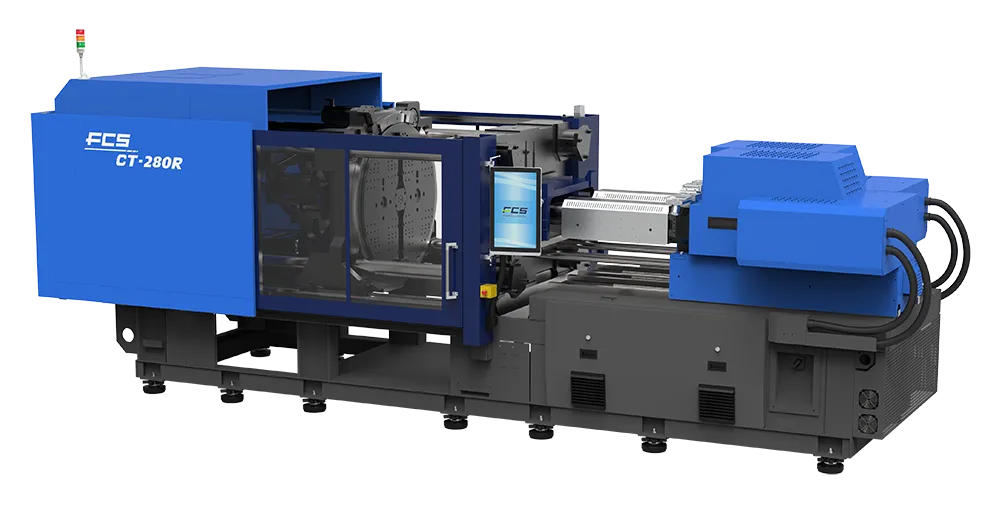

This all-electric two-component injection molding machine is designed for high-efficiency production of dual and multi-component products. Featuring servo motors for rapid mold opening and a four-pillar frame structure at the injection end, it distributes stress evenly for stable molding. This technology enhances multifunctionality and operational efficiency and ensures precise positional control up to 0.01mm. With a clamping force ranging from 180 to 280 tons, this injection molding machine is optimized for precise and controlled molding processes.

130mm-190mm

30g-275g

1650kgf/cm²-3000kgf/cm²

46g/s-434g/s

Perfect for producing multi-color and dual-color plastic products across various industries with high precision requirements, including electronic parts manufacturing, medical supplies, and cosmetic container production.

Equipped with dual or multiple independent material tubes that operate synchronously to reduce cycle times significantly. Screws and barrels are made from special alloy steel with ion nitriding treatment, providing excellent corrosion resistance, wear resistance, and high-temperature tolerance.

Fu Chun Shin, since 1974, is the leading brand of injection molding machine in Taiwan.