Suitable for producing PVC components, our injection molding equipment is engineered to increase production speeds while maintaining high quality. It features a quick-acting hydraulic system for fast mold changes, improving cycle times significantly. Effective airflow management maintains optimal thermal conditions, which is crucial for processing PVC materials that are sensitive to heat. Equipped with a high-torque, low-speed motor, this plastic processing machine ensures precise control over the plasticization process. With a clamping force range from 100 to 1600 tons, this thermosetting molding machine handles various product sizes and complexities with ease.

150mm-585mm

96g-8191g

1396kgf/cm²-2500kgf/cm²

87g/s-1334g/s

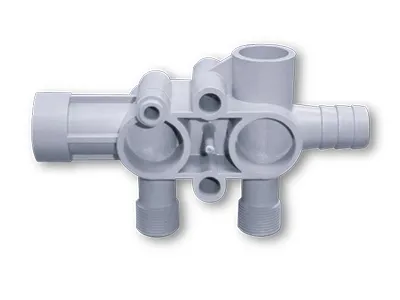

Suitable for the production of PVC fittings used in building and construction. It efficiently manufactures various connection components, including L-shaped elbows, T-connectors, Y-connectors, and flange joints such as ball valves. Our plastic machinery’s precision and adaptability make it perfect for creating durable and complex shapes required in modern infrastructure.

The frame of our injection molding equipment is engineered for exceptional durability. Through the use of advanced finite element analysis, the structure is optimized to resist deformation and distribute stresses evenly, guaranteeing unwavering stability during extensive production runs.

With a focus on reducing operational friction and enhancing speed, the guide pillars of this injection molding machine are coated with molybdenum disulfide. This treatment significantly decreases resistance during movements, ensures high-speed operation without lubrication, and maintains the system’s cleanliness.

Fu Chun Shin, since 1974, is the leading brand of injection molding machine in Taiwan.