Microcellular Foaming Injection Molding

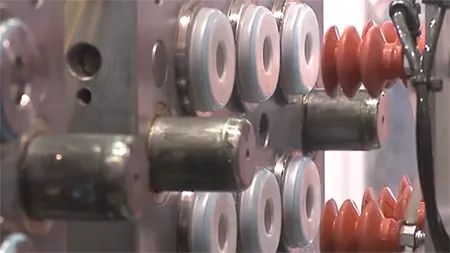

Microcellular foaming injection molding is a plastic processing technique that enhances the production of plastic parts by introducing gas (N2 or CO2) into the melted plastic material. By pressurizing the gas to a supercritical state, it is mixed with the molten plastic to form a single-phase solution. During the injection process, a rapid drop in pressure causes the gas to form uniform microbubbles within the plastic, resulting in a product with a honeycomb-like internal structure.

See MoreGet In Touch

Videos

Company Video

Company Video Plastic Injection Molding Machines at Exhibition

Plastic Injection Molding Machines at Exhibition Rotary Table Two-Component Injection Molding Machine

Rotary Table Two-Component Injection Molding Machine Thin-Wall Injection Molding Machine

Thin-Wall Injection Molding Machine All-Electric Injection Molding Machine

All-Electric Injection Molding Machine All-Electric Two-Component Injection Molding Machine

All-Electric Two-Component Injection Molding Machine Servo-Hydraulic Injection Molding Machine

Servo-Hydraulic Injection Molding Machine Large Rotary Table Two-Component Injection Molding Machine

Large Rotary Table Two-Component Injection Molding Machine Two-Platen Injection Molding Machine

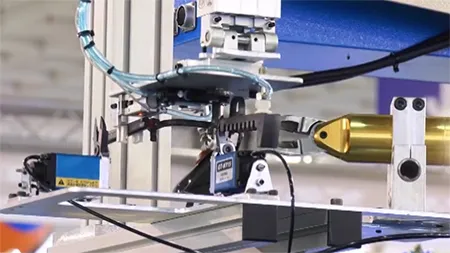

Two-Platen Injection Molding Machine In-Mold Labeling (IML)

In-Mold Labeling (IML) Beverage Packaging Injection Molding

Beverage Packaging Injection Molding Microcellular Foaming Injection Molding

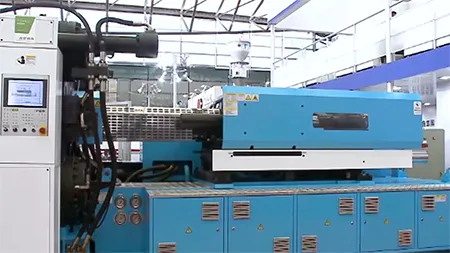

Microcellular Foaming Injection Molding Two-Platen Multi-Component Injection Molding Machine

Two-Platen Multi-Component Injection Molding Machine Bucket Injection Molding Machine

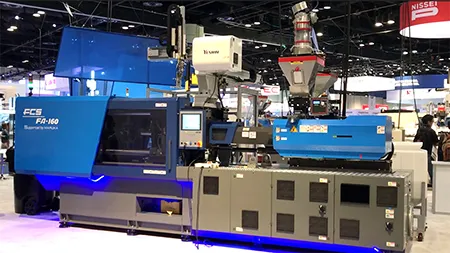

Bucket Injection Molding Machine NPE 2018, USA

NPE 2018, USA Chinaplas 2018, Shanghai

Chinaplas 2018, Shanghai Exhibition in Taipei in 2018

Exhibition in Taipei in 2018 K 2019, in Germany

K 2019, in Germany Chinaplas 2019 in Guangzhou

Chinaplas 2019 in Guangzhou Exhibition in 2019 in Indonesia

Exhibition in 2019 in Indonesia PVI 2020 in India

PVI 2020 in India

Injection Molding System Solution

Injection Molding System Solution